The stations will be equipped with state-of-the-art passenger amenities. Track works over viaducts have also started, and around 157 track km of RC track bed construction has been achieved so far in Gujarat.

Good news for commuters travelling between Mumbai and Ahmedabad, as Japan has begun testing the first Shinkansen bullet trains, integral to the Mumbai-Ahmedabad High-Speed Rail (MAHSR) project. In India's journey to open its first high-speed rail link, this development marks an important turning point.

Japan would give India two Shinkansen bullet trains, one from each of the E5 and E3 series, for early testing and inspections as part of the Indo-Japanese partnership, according to a report by The Financial Express. By early 2026, these high-speed trains, which can travel up to 320 km/h, should arrive in India. Following their arrival, the trains will undergo extensive testing to see how well they function in the local climate and weather of India.

In order to check key factors like driving conditions, temperature tolerance, and dust resistance, all of which are critical for bullet trains to operate smoothly in India, the trial trains are equipped with advanced inspection systems. According to The Japan Times, India will use the data from these tests to help build its next-generation E10 series Shinkansen trains as part of the 'Make in India' campaign.

A major step towards the nation's infrastructure development, the bullet train project in collaboration with Japan is anticipated to increase employment, economic growth, and regional connectivity in the western states of Gujarat and Maharashtra.

NHSRCL said, "Out of 300 km of superstructure, 257.4 km is constructed through Full Span Launching Method (FSLM) including 14 river bridges, 37.8 km through Span by Span (SBS), 0.9 km steel bridges (10 spans ranging from 60 to 130 m in 7 bridges), 1.2 km PSC bridges (20 spans ranging from 40 to 80 m in 5 bridges) and 2.7 km in station building."

For constructing 257.4 km of viaduct through FSLM and 37.8 km of viaduct through SBS, 6455 & 925 spans of 40 m each, respectively, were used.

The project has supported the use of indigenously designed and manufactured equipment such as Straddle Carriers, Launching Gantries, Bridge Gantries, and Girder Transporters for construction. This marks a first for Indian infrastructure, showcasing India's growing capabilities in high-speed rail technology with the support of the Japanese government.

The adoption of the Full Span Launching Method has significantly accelerated construction, as full-span girder erection is up to ten (10) times faster than conventional segmental methods. Each full-span box girder weighs 970 metric tons. Segmental girders are used selectively in locations where full-span installation is not feasible.

To facilitate construction, 27 dedicated casting yards were established along the corridor. Steel bridges are fabricated in seven workshops spread all across the country, three in Gujarat, one each in Uttar Pradesh, Tamil Nadu, Maharashtra and West Bengal truly exemplifying the spirit of unity of our country.

More than 3 lakh noise barriers have been installed along the viaducts to mitigate noise during operations. In addition to the viaducts, the project has also completed 383 km of pier work, 401 km of foundation work, and 326 km of girder casting.

The thematic Bullet Train stations are rapidly taking shape. These stations will be integrated with the rail and road-based transport system to provide seamless travel to passengers. The stations will be equipped with state-of-the-art passenger amenities. Track works over viaducts have also started, and around 157 track km of RC track bed construction has been achieved so far in Gujarat.

The rolling stock depots with modern infrastructure are also getting ready in Maharashtra and Gujarat. This milestone is a demonstration of the project's robust planning, cutting-edge engineering, and commitment to the "Make in India" policy

(with inputs from ANI)

ED conducts raids at businesses linked to Anil Ambani

ED conducts raids at businesses linked to Anil Ambani Anant Ambani, Radhika Merchant visit London's Swaminarayan Temple days after their first wedding anniversary, Mukesh Ambani joins them, watch viral video

Anant Ambani, Radhika Merchant visit London's Swaminarayan Temple days after their first wedding anniversary, Mukesh Ambani joins them, watch viral video Hari Hara Veera Mallu X review: Pawan Kalyan creates 'mass hysteria' in cinemas, fans hails his film 'perfect blend' of emotions with 'rich visuals'

Hari Hara Veera Mallu X review: Pawan Kalyan creates 'mass hysteria' in cinemas, fans hails his film 'perfect blend' of emotions with 'rich visuals' Bad news for employees as this IT giant delays onboarding, 600 left without job, not Narayana Murthy's Infosys, Azim Premji's Wipro, Google, Amazon, it is...

Bad news for employees as this IT giant delays onboarding, 600 left without job, not Narayana Murthy's Infosys, Azim Premji's Wipro, Google, Amazon, it is... Gita Gopinath's IMF salary vs Harvard salary: How much will IMF deputy managing director earn when she returns to Harvard University in August

Gita Gopinath's IMF salary vs Harvard salary: How much will IMF deputy managing director earn when she returns to Harvard University in August Iphone Fold: Apple’s iPhone Fold Could Solve Samsung’s Biggest Foldable Problem | Samsung Z Fold 7

Iphone Fold: Apple’s iPhone Fold Could Solve Samsung’s Biggest Foldable Problem | Samsung Z Fold 7 Trump News: Congress Seeks Answers On Trump's Alleged Mediation In Operation Sindoor

Trump News: Congress Seeks Answers On Trump's Alleged Mediation In Operation Sindoor Odisha News: Minor Burnt To Death In Puri Family Reveals Shocking Attack Details | Puri News

Odisha News: Minor Burnt To Death In Puri Family Reveals Shocking Attack Details | Puri News Odisha News: Minor Girl Burnt By 3 Men Days After Balasore Self-Immolation | Puri News

Odisha News: Minor Girl Burnt By 3 Men Days After Balasore Self-Immolation | Puri News Saiyaara: Who Is Ahaan Panday, Ananya’s Cousin, To Debut In YRF’s Mohit Suri Love Story

Saiyaara: Who Is Ahaan Panday, Ananya’s Cousin, To Debut In YRF’s Mohit Suri Love Story ED conducts raids at businesses linked to Anil Ambani

ED conducts raids at businesses linked to Anil Ambani Bad news for employees as this IT giant delays onboarding, 600 left without job, not Narayana Murthy's Infosys, Azim Premji's Wipro, Google, Amazon, it is...

Bad news for employees as this IT giant delays onboarding, 600 left without job, not Narayana Murthy's Infosys, Azim Premji's Wipro, Google, Amazon, it is... Narayana Murthy's Infosys gives BIG update on salary hike, says, ‘Next one we'll have to…’

Narayana Murthy's Infosys gives BIG update on salary hike, says, ‘Next one we'll have to…’ Meet Eva Jobs, daughter of Steve Jobs, set to marry Harry Charles in lavish wedding worth Rs..., know who is richer

Meet Eva Jobs, daughter of Steve Jobs, set to marry Harry Charles in lavish wedding worth Rs..., know who is richer  Blackrock prohibits employees from using...in China, know why US companies are struggling to operate in China

Blackrock prohibits employees from using...in China, know why US companies are struggling to operate in China  From Baa to Gomzy, these Kyunki Saas Bhi Kabhi Bahu Thi characters we won't see again in reboot

From Baa to Gomzy, these Kyunki Saas Bhi Kabhi Bahu Thi characters we won't see again in reboot Veer-Zaara to Kal Ho Naa Ho: 7 unforgettable Bollywood love stories that still make us cry

Veer-Zaara to Kal Ho Naa Ho: 7 unforgettable Bollywood love stories that still make us cry Kollywood star Suriya turns 50: A look at his net worth, best films, what’s next for the Karuppu actor

Kollywood star Suriya turns 50: A look at his net worth, best films, what’s next for the Karuppu actor Sonu-Titu to Bikram-Bala: 5 legendary Bollywood duos who gave us friendship feels

Sonu-Titu to Bikram-Bala: 5 legendary Bollywood duos who gave us friendship feels How rich is Yuzvendra Chahal? A peek into cricketer's Rs 45 crore net worth, IPL salary, luxury life

How rich is Yuzvendra Chahal? A peek into cricketer's Rs 45 crore net worth, IPL salary, luxury life Who is Harshvardhan Jain? Ghaziabad man busted for running fake embassy posing as diplomat, UP STF seizes 4 luxury cars, Rs 44 lakh cash, and...

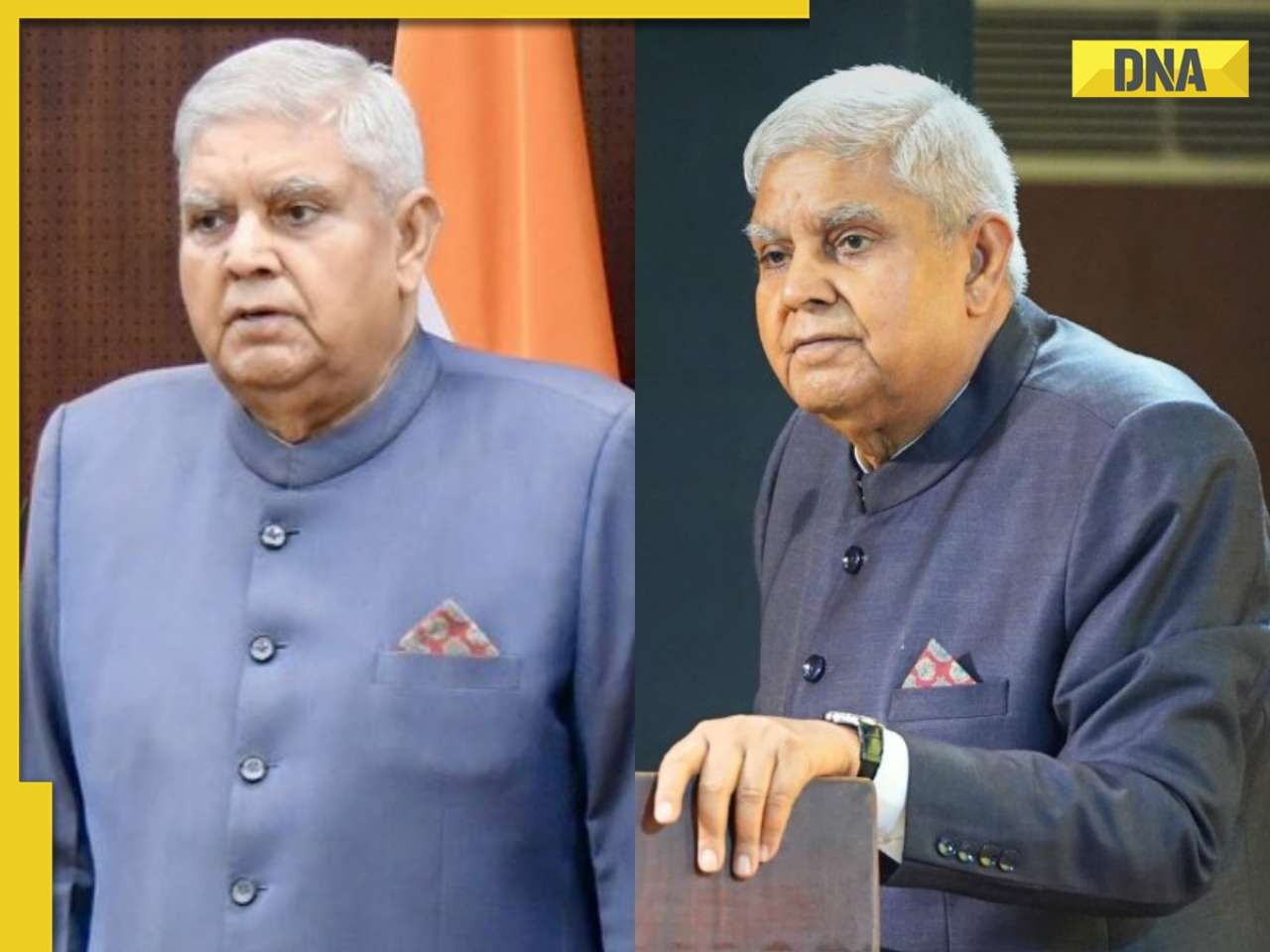

Who is Harshvardhan Jain? Ghaziabad man busted for running fake embassy posing as diplomat, UP STF seizes 4 luxury cars, Rs 44 lakh cash, and... DNA Verified: Jagdeep Dhankhar asked to vacate his official residence immediately? Know the truth behind viral claim

DNA Verified: Jagdeep Dhankhar asked to vacate his official residence immediately? Know the truth behind viral claim Shocking! Tiger Hide, expensive liquor among assets worth whopping Rs...,found in raid on massive properties

Shocking! Tiger Hide, expensive liquor among assets worth whopping Rs...,found in raid on massive properties  Gujarat ATS arrests 4 al-Qaeda linked terrorists from...; Accused of spreading Islamic propaganda through...

Gujarat ATS arrests 4 al-Qaeda linked terrorists from...; Accused of spreading Islamic propaganda through... Delhi Rains: Yamuna 0.37 metre away from its WARNING level as water reaches...

Delhi Rains: Yamuna 0.37 metre away from its WARNING level as water reaches... Meet woman, IIT grad who left high-paying job to crack UPSC exam, got AIR..., now posted at...

Meet woman, IIT grad who left high-paying job to crack UPSC exam, got AIR..., now posted at... Meet IAS officer, IIT graduate who cracked UPSC, climbed Mount Everest twice, currently posted in..., his name is...

Meet IAS officer, IIT graduate who cracked UPSC, climbed Mount Everest twice, currently posted in..., his name is... Meet Samaira Hullur, who cracked 6 aviation exams to become India's..., she is from...

Meet Samaira Hullur, who cracked 6 aviation exams to become India's..., she is from... Meet woman who cleared UPSC exam in her 7th attempt at age 40, after becoming a mother of two, became IAS officer with AIR...

Meet woman who cleared UPSC exam in her 7th attempt at age 40, after becoming a mother of two, became IAS officer with AIR... Meet woman who cracked UPSC exam in first attempt at the age of 21 with AIR..., but did not become IAS, IPS due to..., currently she is working in...

Meet woman who cracked UPSC exam in first attempt at the age of 21 with AIR..., but did not become IAS, IPS due to..., currently she is working in... Maruti Suzuki's e Vitara set to debut electric market at Rs..., with range of over 500 km, to launch on...

Maruti Suzuki's e Vitara set to debut electric market at Rs..., with range of over 500 km, to launch on... This is world’s most expensive wood, cost of 1kg wood is more than gold, its name is..., is found in...

This is world’s most expensive wood, cost of 1kg wood is more than gold, its name is..., is found in... This luxury car is first choice of Indians, even left BMW, Jaguar, Audi behind in sales, it is...

This luxury car is first choice of Indians, even left BMW, Jaguar, Audi behind in sales, it is... Kia India unveils Carens Clavis: Check features, design changes, price and more; bookings open on...

Kia India unveils Carens Clavis: Check features, design changes, price and more; bookings open on... Tesla CEO Elon Musk launches most affordable Cybertruck, but it costs Rs 830000 more than older version, it is worth Rs...

Tesla CEO Elon Musk launches most affordable Cybertruck, but it costs Rs 830000 more than older version, it is worth Rs...

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)